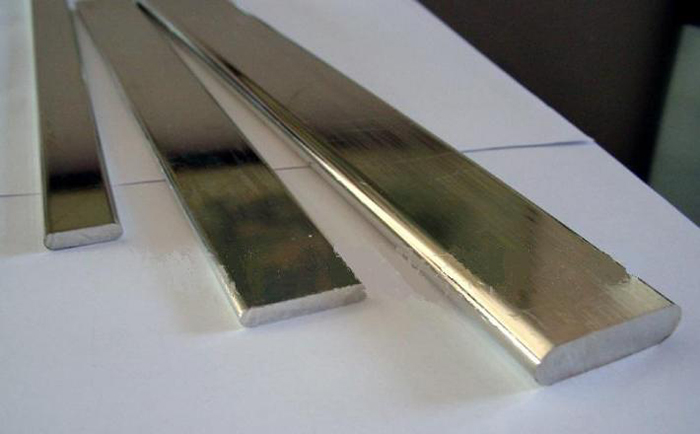

Tin Plated Aluminum Bus Bar

Aluminum bus bar products.

Tin plated aluminum bus bar. Our aluminum bus bar engineers can help you choose the right type of aluminum and the best way to custom manufacture it to meet the most demanding applications. When you choose storm to perform electroplating services you ll regain control over quality and mitigate exposure to extended lead times. Tin plated bus bars have a low operating window because of a low melting point around 450 f. Aluminum is critical to a diverse range of applications in industries ranging from transportation electronics and construction to packaging household items and recreational products.

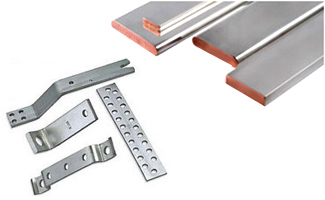

We are pleased to announce that online metals is now carrying tin plated and silver flashed copper bars. Our design capabilities include complete machining forming brazing welding processes plus plating powder coating services. These bars are copper alloy c110 h02 half hard with full round edges and a thin covering of tin or silver flashing. However silver plating is usually better because it s tougher and further improves conductivity.

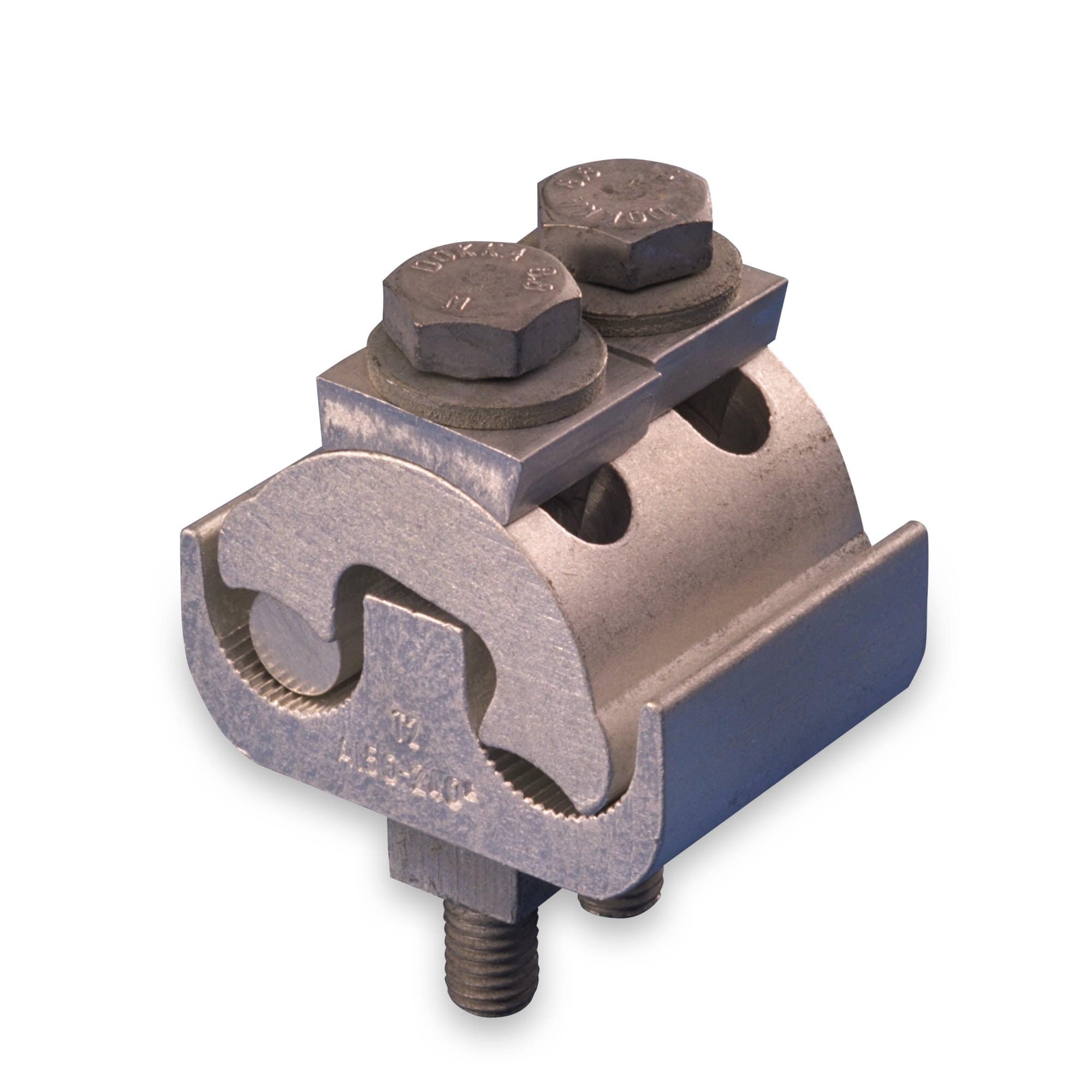

Aluminum base metal is pretreated with the alstan surface preparation process to enhance adhesion strength of the coating metal. So both tin directly on aluminum and tin on copper on aluminum are common. Aluminum bus bar vs copper the primary differences between aluminum and copper bus bar is that aluminum is more cost effective and lighter weight. Bus bar plated with copper then tin turns black over time june 27 2010 q.

Tin plating is susceptible to whiskering small metal filament growth which could cause unwanted bridges to electronics. Advanced custom aluminum bus bar design and manufacturing. Yes entire manufacturing plants have been devoted to making aluminum bus bar and plating it with copper. Wmwa enables companies to fulfill their project requirements with a wide selection of excellent quality aluminum bus bar products.

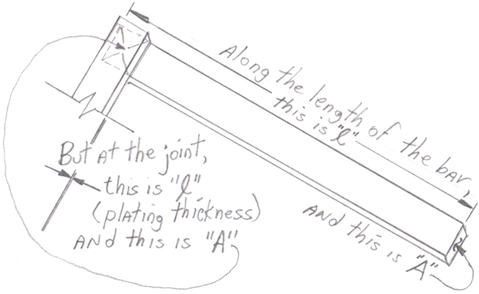

When the plated copper components are returned for testing even the slightest scratch in the plated surface can mean a failed inspection. If components operate above these temperatures then nickel would be suggested. Aluminium busbar is tin plated using copper as undercoat 3 microns upon which tin is coated 6 microns. Over a period of time the busbar turns blackish.

T6 aluminum bar a layer of 0 1mm thick pure nickel plate is welded on a layer of 1060 0 aluminum plate it is widely used in the battery moudel connection which can effectively prevent the electrochemical corrosion caused by copper aluminum bonding also it has very good vibration resistance. Atotech used to offer and may still offer their alstan process for plating aluminum directly with tin skipping the copper plating step.